From Sketch to Steel: Crafting the Shieldon Hierophant EDC Knife with CAD

Crafting Perfection: The Birth of the Shieldon Hierophant

Introducing the Hierophant: A Perfect Blend of Aesthetics and Functionality

The Shieldon

Hierophant is not just a tool; it is a masterpiece that encapsulates the

essential balance of form and function. Designed with the user in mind, it

delivers on the promise of being a reliable Everyday Carry (EDC) companion that

doesn’t compromise on style or ergonomics. The conception of such a blend

requires meticulous planning and precision, traits that are at the heart of the

Hierophant’s design philosophy.

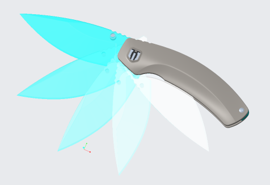

The CAD Journey: From Concept to Reality

The

transition from a hand-drawn sketch to a fully functional knife is an intricate

process. It begins with a vision, one that sees past the realm of possibility

and into the practicality of creation. This journey, paved with advanced CAD

(Computer-Aided Design) techniques, brings to life the complex interplay of

components that form the Hierophant. CAD drawing expresses not only the knife’s

physical form but also its soul – the way it feels in the hand and responds to

the user’s intent.

From the

early drafts penned by a passionate designer named Matt, to the scrupulous

discussions with Shieldon on blade curvature and handle ergonomics, every step

in the CAD drawing process is a dance between functionality and aesthetic

appeal. Despite his lack of engineering software expertise, Matt’s dedication

as a knife enthusiast shines through, his sketches progressively evolving into

the precise lines and curves of the Hierophant.

The

decision-making saga from the back spine of the blade to the innovative 95%

deep carry clip, culminates in a CAD blueprint that is more than a mere

assembly of metal and material. It is the embodiment of a shared vision to

create a superlative EDC knife. Each component, measured with an accuracy up to

0.01mm, comes together in a symphony of design and engineering excellence. The

Hierophant's graceful silhouette and the choice of honeydew G10 for the

contoured handle, paired with jade G10 for the backspacer, are not just design

choices; they are statements of intent and purpose.

This journey

from sketch to CAD, and finally to a tangible, high-performance EDC knife, is a

testament to the skill and passion driving the Shieldon brand. Each step is a

reflection of the dedication to create something that is not only useful but

also inspiring – a knife that cuts through the mundane and opens up the

potential for greatness in everyday tasks. The Shieldon Hierophant, with its

CAD-conceived curves and edges, is set to become an icon in the EDC space,

bridging the gap between mere concept and high-quality reality.

Unveiling the Vision: The Genesis of the Hierophant Design

Meeting Matt: A Knife Enthusiast's Vision

For many, a

knife is simply a tool, but for Matt, it's a canvas of expression. A new

designer with a long-standing passion for knives, Matt approached Shieldon with

a concept unlike any other. Despite lacking formal training in engineering

software, his sketches brimmed with potential. His ideas, drawn from years of

dedication to the craft, yearned for the right collaborator. Shieldon,

recognizing the raw talent and shared ambition, embraced the opportunity for a

creative partnership. With this alliance, the Hierophant—named for its mystical

allure—began its journey from a rough sketch to an exquisite piece of

engineering.

Initial Sketch Discussions with Shieldon

In the

embryonic stages of design, Matt's talkative nature proved advantageous. Every

stroke of his pencil laid the foundation for what would become Shieldon's first

royalty design. Poring over numerous drafts, Matt's iterative process—a blend

of persistence and learning from existing designs—slowly refined the

Hierophant's blade to perfection. Shieldon's team, equally meticulous and

visionary, engaged in spirited debates over every aspect, from the blade's back

spine to the handle's contour.

Crafting a

contoured G10 handle swiftly followed, with an understanding that aesthetic

appeal should never compromise functionality. Yet, the discussions were far

from over. The minute detail of the pocket clip's position sparked further

debate. Should it offer complete concealment, or should practicality prevail?

The solution: a profound compromise that ensured a 95% deep carry while still

allowing for easy access and draw from the pocket.

From Idea to CAD: Translating Vision into Precision

The

methodology behind the Hierophant's creation was as rigorous as it was

creative. Every component underwent meticulous scrutiny, ensuring that when

joined, they would form a seamless, robust structure. The precision of CNC

engineering came to the fore here, demanding measurements within a hundredth of

a millimeter's tolerance and accepting no more than a two-tenths of a

millimeter discrepancy during manufacturing.

The CAD

process brought the Hierophant's internal anatomy to light, revealing the

intricate interplay between form and function. It's not just about creating a

single item that meets Shieldon's stringent criteria for aesthetics and

ergonomics—it's about setting a precedent for all future creations.

Perhaps the

most crucial element affecting the Hierophant's functionality was the pivot—a

component instrumental in the knife's deployment. Ensuring its exact rotation

was a process of continuous testing and re-testing, a dance between the CAD

model and the unforgiving reality of mechanics. Achieving the perfect fit meant

not only a safe deployment but also the embodiment of the Hierophant's

mysterious and powerful essence.

With the

pivot in place, the Hierophant was almost ready to step off the screen and into

the hands of those who would appreciate its blend of ancient mystery and modern

craftsmanship. Its closed blade nestled perfectly within the handle, promising

a firm grip and a significant choil for precise control during use.

Honoring the Name: Selecting the Hierophant's Colors

The naming

of the knife was a pivotal moment, with the Hierophant's symbolism resonating

through its form. A light color palette, suggestive of purity and the sacred,

was chosen to reflect the knife's namesake—a guide to the holy and the

mysterious. Preparing for CNC production, the CAD model underwent one final

review, refining components like the thumb stud to ensure flawless assembly.

Ultimately,

the choice of honeydew G10 for the handle and jade G10 for the backspacer not

only set the Hierophant apart in the market but also imbued it with the sublime

aura of cathedral spaces and divine light. These final touches completed the

Hierophant's CAD journey—a journey from the realms of imagination, through the

exacting demands of design and engineering, culminating in a knife that stands

as a testament to the sacred union of form and function.

Blade Design: The Heart of the Hierophant

Ideation and Refinement of Blade Features

The blade is

the soul of any knife, and the design of the Shieldon Hierophant's blade began

with Matt's fervent aspirations. Untrained in engineering software but rich in

enthusiasm and experience, Matt's initial sketches signaled the birth of an

extraordinary EDC knife. His many drafts, though not all immediately practical,

were the seeds of innovation that, once refined, would germinate into the

Hierophant's standout features.

The Perfectionist's Pursuit with Shieldon

Matt's

dialogue with Shieldon was a meticulous pursuit of excellence. His

perfectionism, matched by Shieldon's commitment to quality, meant no feature

was too small for debate. The blade's back spine, a distinctive feature of the

Hierophant, was discussed and reimagined until it reached an ideal form. This

collaborative, detail-oriented approach ensured that the blade was not only

visually striking but also functionally superior.

During the

CAD drawing process, the team's synergy was palpable. The blade's features took

shape with precision, moving from abstract ideas to tangible elements. Debates

around the blade’s spine curvature and the handle ergonomics transitioned into

decisions that balanced aesthetic allure with tactical efficiency.

The G10

handle was sculpted to complement the blade's design, leading to an expedited

completion of the knife's look. However, true to the nature of a

perfectionist's journey, the design team was soon immersed in discussions

regarding the pocket clip's placement. The result was a harmonious agreement on

a deep carry clip that allowed for ease of access while maintaining the

Hierophant's sleek profile.

Translating Design to Precision

Every

component, from the blade to the pocket clip, was dissected and meticulously

measured, ready to be recreated in the virtual world of CAD with exacting

standards. This digital translation was more than just drafting—it was the

transformation of a dream into a blueprint for reality.

The entire

knife, when viewed through the lens of the CAD software, became a transparent

marvel—revealing the Hierophant’s inner structure and confirming its

measurements. The blade length and overall size were not just numbers but

represented a commitment to creating a knife that felt right in the hand of its

bearer.

As the

design moved closer to completion, the pivot's placement was perfected through

relentless testing. This critical element, pivotal for the smooth unfolding of

the blade, had to be placed with absolute precision to ensure safety and

functionality.

With the

pivot's successful integration, Matt's vision was realized in the engineering

imagery of the Hierophant—a knife that not only promised exceptional

performance but also carried the mystique of its name. The choice of a pure,

light color for the G10 handle was not merely aesthetic but also symbolic,

resonating with the Hierophant's sacred inspiration.

Before

advancing to CNC machining, a final review was undertaken to fine-tune each

component, including the thumb stud's placement, ensuring the knife’s integrity

and readiness for production. The CAD journey, filled with rigorous testing and

passionate discussions, brought to life a knife that exemplified the artistry

and precision that Shieldon and Matt collectively envisioned.

The

Hierophant stands as a testament to the transformative power of collaboration,

from an enthusiast's persistent drafts to Shieldon's expert refinement—a knife

not only designed to perform but also to inspire.

Crafting the Handle: The Grip of Elegance

Quick Consensus on a Contoured G10 Handle

The handle

of a knife is where the hand meets the tool, and for the Shieldon Hierophant,

this interaction is paramount. The journey of crafting the Hierophant's handle

began with a rapid agreement on the use of G10 material, known for its

durability and grip. Shieldon's collaboration with Matt quickly solidified the

choice for a contoured handle that would ensure comfort and control. The CAD

drawing process for the handle was initiated with an emphasis on ergonomic

design, allowing a natural, secure fit in the user's palm. This swift consensus

on the handle's material and shape allowed the team to transition smoothly into

the more intricate aspects of the knife's design.

The Pocket Clip Debate: Balancing Concealment and Accessibility

A vital yet

often underrated component, the pocket clip's placement was a subject of

intense discussion. The key was to strike an optimal balance between deep

concealment within the pocket and easy accessibility. The team's dedication to

detail led to a design that offers a 95% deep carry pocket clip. This strategic

positioning allows a small portion of the knife to remain visible and

accessible, giving users the ability to draw the knife quickly and

effortlessly. The CAD process aided in visualizing and testing various

placements for the clip, ensuring that the final design would not compromise on

functionality or the Hierophant's sleek silhouette.

The CAD Drawing Process: Precision Meets Design

After the

rigorous discussion and decision-making, the focus shifted to bringing the

handle to life through CAD. Measurements and specifications for each component

were taken with utmost precision, adhering to strict standards that would

ensure seamless assembly later in the manufacturing process.

The CAD

software allowed the team to view a transparent model, visualizing the

symbiotic relationship between the blade and handle. It was imperative that

when closed, the blade would align flawlessly with the handle, maintaining the

Hierophant's streamlined design while also providing a substantial choil for

safety and control during use.

Each

discussion, each decision, and each measurement served a purpose: uniting form

and function in a harmonious design that could only be achieved through the

meticulous CAD drawing process. This stage was crucial in setting the stage for

the next, where the aesthetic choices would bring the Hierophant's character to

full expression.

Precision Engineering: Component Measurement

Breaking Down the Knife Into Components

In the world

of EDC knives, precision is not just a goal, it's a necessity. For the Shieldon

Hierophant, the journey from a conceptual design to a tangible product begins

with breaking down the knife into its individual components. This step is

crucial in understanding the interaction between each part and ensuring a

harmonious assembly. Utilizing CAD software, each piece of the Hierophant is

meticulously drafted, with dimensions and geometry carefully plotted to build a

knife that's both beautiful and functional.

The Rigor of CNC Engineering and Tolerances

The art of

knife-making meets the precision of engineering in the realm of CNC machining.

For Shieldon's Hierophant, achieving the required tight tolerances is a

testament to the partnership between man and machine. Every measurement, down

to the last 0.01mm, is scrutinized and adhered to, ensuring that each element

of the knife aligns and functions without fault. In the CAD environment, these

measurements come to life, providing a virtual blueprint that leaves no room

for error—a blueprint that CNC machines will follow to create each component of

the Hierophant with unparalleled accuracy.

For the

Hierophant, the CAD process is not merely about converting sketches into

digital drawings; it's about embodying Shieldon's dedication to precision in

every curve, edge, and surface. This process not only tests the skill of the

engineers but also sets the standard for the manufacturing phase, where even a

minor deviation of 0.2mm is deemed unacceptable. The CAD drawings serve as the

foundation for the exceptional quality of the final product, ensuring that the

Hierophant is not just another knife in the market, but a paragon of EDC knife

excellence.

The

meticulous nature of this phase is critical, as it directly impacts the

assembly and overall performance of the Hierophant. By valuing precision at

this stage, Shieldon guarantees a knife that not only meets the practical

demands of everyday carry but also the high expectations of knife aficionados

everywhere.

Visualizing the Internal Structure

Assessing the Transparent Inner Structure

When

crafting a knife like the Shieldon Hierophant, visualizing the inner structure

is a critical step in the design process. Using advanced CAD (Computer-Aided

Design) techniques, our engineers render the knife's internal framework with a

high degree of transparency. This virtual transparency is essential—it allows

for an in-depth examination of how each component fits together and interacts.

By scrutinizing the CAD model, engineers ensure that every piece, from the

pivot to the locking mechanism, aligns perfectly, avoiding any functional

mishaps after production.

Ensuring Ergonomics and Aesthetic Standardization

Beyond the

structural integrity, the CAD process serves a dual purpose by allowing for the

assessment of the knife's ergonomics and aesthetics. The Hierophant's design is

not only about looking good—it's about feeling right in the hand of the user.

Through the virtual model, engineers and designers can simulate the grip,

balance, and overall feel of the knife. This process ensures that the

Hierophant meets Shieldon's rigorous standards for ergonomic comfort and visual

appeal, which are key to the brand's reputation in the EDC community.

During the

CAD drawing phase, the team meticulously evaluates the knife's shape and size,

constantly iterating to achieve the perfect blend of form and function. For the

Hierophant, this meant measuring the blade at 3.39 inches (86mm) and the

overall length at 7.87 inches (200mm), ensuring the knife is both manageable

and effective. By marrying the technical precision of CAD with the artistry of

knife design, Shieldon sets the bar high, creating EDC knives that are both

objects of beauty and practical tools for daily use.

The Pivot Challenge: Ensuring Safe Deployment

Importance of Pivot Positioning in Knife Design

In the

architecture of any folding knife, the pivot holds a place of critical

importance. It's the heart of the knife's opening and closing mechanism. For

the Shieldon Hierophant, the pivot isn't just a functional detail; it's a

central focus in the design process, demanding careful consideration and

precise positioning. CAD technology allows for an exacting approach to this

challenge, enabling designers to meticulously plan the pivot's placement in

relation to the other moving parts, ensuring a smooth and safe deployment of

the blade with every flick or push.

Rigorous Testing for Optimal Functionality

The pivot's

role in the safety and functionality of a folding knife cannot be overstated.

That's why the Shieldon team invests considerable time in the rigorous testing

of the pivot design. Through a series of simulations within the CAD software,

the pivot undergoes virtual stress tests, checking for any potential

misalignment that could cause unsafe blade exposure or damage to the knife's

internal structure. These tests are repeated, with the pivot's design being

tweaked and refined until the CAD model confirms that the Hierophant's blade

will deploy smoothly and lock securely, ensuring the user's safety and the

knife's longevity.

This

attention to detail in the pivot's design illustrates Shieldon's commitment to

quality and reliability. By leveraging their extensive EDC knife expertise and

advanced CAD drawing skills, they create a product that not only meets but

exceeds the standards set by knife enthusiasts and everyday users alike. This

focus on pivot perfection is a key element that makes the Hierophant a standout

piece in any EDC collection.

Naming the Masterpiece: Hierophant Emerges

Finalizing the Engineering Imagery

With the

components meticulously crafted and the pivot challenge mastered, the

engineering imagery of the Shieldon Hierophant approaches its final form.

Designer Matt's vision, realized through precise CAD drawings, is more than

just a sketch; it's a blueprint for a knife that balances form with function,

innovation with tradition. This stage is about refining those images into a

complete, cohesive representation of the knife, ensuring every line, curve, and

edge aligns with Shieldon's stringent quality standards.

The Mystery and Power Behind the Name "Hierophant"

The

Hierophant is not just a name; it's an embodiment of the knife's essence. In

ancient traditions, the hierophant was a guide, revealing sacred and hidden

truths. Similarly, the Shieldon Hierophant is designed to be more than just a

tool; it's a symbol of mastery and mystery, offering its bearer the power to

explore the depths of their capabilities. The name was chosen to reflect the

knife's potent blend of practicality and profound design philosophy, making it

a talisman for the modern-day adventurer.

Through

CAD's digital medium, this knife transitions from an abstract idea to a revered

icon, ready to be introduced to the world. The Hierophant name serves as a

final touch, a testament to the transformative journey from a designer's dream

to a fully-realized Shieldon masterpiece. As the imagery is finalized and the

name bestowed, the Hierophant stands ready to carve its mark into the annals of

EDC knife history.

Blade and Handle Synchronization

Ensuring Cohesion Between Blade and Handle

In the

detailed journey of drawing the Shieldon Hierophant by CAD, synchronization

between the blade and the handle is paramount. This is not just about ensuring

that the two fit together aesthetically, but also that they operate in seamless

harmony. CAD drawing skills are applied to adjust the dimensions and contours

of both elements, guaranteeing a perfect fit. This cohesion is critical for the

smooth operation of the knife and for providing the user with confidence in its

performance.

Adding Safety Features and Ergonomic Considerations

Safety is a

priority in EDC knife design, especially for a brand like Shieldon. CAD

technology is instrumental in integrating safety features such as a locking

mechanism that aligns perfectly with the blade when opened. Additionally,

ergonomic considerations are key for user comfort and ease of use. The

Hierophant's handle is designed with contours that fit naturally in the hand,

and the balance between the blade and handle is fine-tuned to ensure optimal

control and cutting efficiency. These elements are meticulously planned and

tested in the CAD environment, ensuring that the final product is not only safe

to use but also a pleasure to handle.

Choosing the Color: The Final Aesthetic Decision

The Deliberation Over G10 Color Choices

Selecting

the perfect hue for the Shieldon Hierophant's G10 handle is not just a matter

of aesthetics; it's the crowning touch that enhances the tactile and visual

experience of the user. This final color choice is critical, as it must

complement the intricate design work that has been realized through the

CAD-driven process. The team at Shieldon knows that the color of the handle is

not merely a shade but a statement—one that speaks to the craftsmanship and

artistry of the knife.

Matching the Color to the "Hierophant" Theme

Matching the

color to the Hierophant theme required a thoughtful approach. The name itself

invokes a sense of ancient wisdom and mystique—qualities that are visually

represented through color symbolism. After extensive collaboration and

consideration, the choice became clear: a light, pure hue that embodies the

essence of the Hierophant's sacred significance. CAD technology played a

pivotal role in visualizing how different colors would look on the finished

product, ensuring that the selected G10 material would not only align with the

Hierophant's theme but also attract the discerning eyes of knife enthusiasts

and collectors. The chosen palette is intended to evoke the knife's unique

identity and resonate with the spiritual connotations of its namesake.

The Sacred Symbolism of the Hierophant Knife

Understanding the Hierophant's Symbolic Representation

The design

of the Shieldon Hierophant knife carries deep symbolic significance,

transcending its physical form to become a metaphor of enlightenment and

guidance. In CAD, every line and curve is drawn not only with precision but

also with a conscious integration of the Hierophant's symbolic representation.

The knife, through its meticulous design, aims to embody the bridge between the

mundane and the sacred, mirroring the role of a hierophant in ancient rituals.

The Knife as an Extension of Religious and Arcane Principles

In the realm

of EDC knives, the Hierophant stands out as an extension of religious and

arcane principles, blending the practical with the mystical. The CAD drawing

process ensures that every aspect of the knife, from the sweeping arc of the

blade to the ergonomically designed handle, is a testament to these principles.

This design philosophy elevates the utilitarian object to an artifact that

holds more than just edge retention and grip comfort—it holds meaning. The

Hierophant knife becomes a talisman for those who carry it, a daily reminder of

the unseen forces and guiding principles that influence our lives.

Pre-production Checks and Balances

The Critical Role of Revisiting Component Organization

Before the

Shieldon Hierophant transitions from model to market, a rigorous phase of

pre-production checks is essential. These checks involve revisiting the

organization of components within the CAD software. CAD experts meticulously

review each element, ensuring that the assembly is logical, functional, and

aesthetically consistent. This process is not just about technical precision

but also about maintaining the integrity of the original design throughout the

production phase.

Spotting and Correcting Last-Minute Design Flaws

The final

stages of CAD drawing are critical for spotting and correcting any last-minute

design flaws that could compromise the functionality or safety of the knife. It

is during this phase that the expertise of the CAD drafter combines with the

practical knowledge of EDC knife engineering to scrutinize every millimeter of

the Hierophant. Any necessary adjustments, such as repositioning the thumb stud

for optimal use, are made with an accuracy of up to 0.01mm. This attention to

detail ensures that each Shieldon Hierophant knife is not only a reflection of

exquisite craftsmanship but also a reliable tool in the hands of its user.

Finalizing Materials: Honeydew and Jade G10 Selection

The Selection of Unique G10 Materials for Handle and Backspacer

For the

Shieldon Hierophant, the selection of materials is as significant as the design

itself. The CAD process extends beyond shapes and dimensions; it's about

bringing the envisioned knife to life with the right materials. For the handle

and backspacer, the choice fell on unique G10 composites—honeydew and jade.

These materials are not only durable, offering resilience and a secure grip,

but they also provide a distinct visual appeal that sets the Hierophant apart

from other EDC knives.

The Hierophant's Final Look: A Reflection of Sacred Spaces

The final

look of the Hierophant knife, achieved through CAD rendering, reflects the

solemn beauty of sacred spaces. Honeydew G10, chosen for the handle, casts a

serene light reminiscent of stained glass, inviting calm and focus. The

backspacer, in jade G10, acts as an accent piece, echoing the tranquil and

meditative spaces of a sanctuary. This thoughtful selection of materials

ensures that the Hierophant is not just a tool but a work of art, imbued with a

sense of peace and purpose that transcends its physical form.

Conclusion

Summarizing the Journey from Sketch to CAD to CNC

The Shieldon

Hierophant's creation has been a meticulous journey from a passionate

designer's sketch to a precise CAD model, and finally to the hands of skilled

CNC technicians. Each step, guided by expertise in both CAD drafting and EDC

knife design, has been essential in transforming an inspired concept into a

tangible, high-quality knife.

The Hierophant: Ready for Production and EDC Enthusiasts

Now

finalized with unique honeydew and jade G10 materials, the Hierophant stands

ready for production. This knife isn't just a tool; it's a piece of carriable

art, eager to make its mark in the pockets of EDC enthusiasts. With a design

that channels the mysterious allure of its namesake, the Shieldon Hierophant is

set to become a cherished part of any collection, equally at home in display

cases or in the hands of those who appreciate fine craftsmanship.

Call to Action

An Invitation to Engage with Shieldon for Custom Knife Projects

Are you

inspired by the precision and creativity that brought the Shieldon Hierophant

to life? We at Shieldon invite you to bring your custom knife projects to our

table. Our team is eager to collaborate with designers, knife enthusiasts, and

anyone with a vision for a unique EDC knife. Let's forge your ideas into

reality with our advanced CAD drawing skills and comprehensive knife-making

expertise.

Encouraging Feedback and Collaborative Design Opportunities

We're not

just about crafting fine knives; we're about building a community. Share your

thoughts on the Hierophant, provide feedback on our process, or pitch your own

design. Your insights are invaluable, and we welcome the opportunity to

innovate together. Connect with Shieldon today, and let's create something

exceptional.

Appendix: CAD Drawing Tips and Tricks

Enhancing CAD Skills for EDC Knife Creation

Advancing

your CAD skills opens up a world of precision and artistry in the craft of EDC

knife creation. As we've explored in the development of the Shieldon

Hierophant, attention to detail in the CAD process is crucial. To enhance your

CAD drawing skills, focus on learning the shortcuts and features specific to

knife design, such as contour mapping for handles and the precise alignment of

locking mechanisms. The right CAD techniques can turn a good design into a

great one, with every curve and angle contributing to the knife's aesthetic and

functionality.

Expert Advice for Aspiring Knife Designers

For aspiring

knife designers, CAD proficiency is key. Start with basic tutorials, then

gradually tackle more complex projects, such as folding mechanisms and

ergonomic handle designs. Remember that patience and practice are your best

tools. Regularly seek feedback from seasoned designers, and don’t hesitate to

iterate on your designs. Utilize simulation features to test the mechanical

aspects of your knife, ensuring a smooth transition from screen to steel. With

these tips and dedicated practice, you'll be on your way to crafting knives

that stand out in both form and function.

Leave your comment

Note: HTML is not translated!